MilSpecWest’s MSWD line covers most standard applications

AEROSPACE MEDICAL AUTOMOTIVE INDUSTRIAL MICRO-ELECTRONICS

MSWD Micro-D connectors are used in applications requiring highly reliable, extremely small, lightweight connectors with higher density contact configurations than available in traditional rectangular connectors. They are available in 7 shell sizes accommodating from 9 to 51 contacts with additional special arrangements available. These connectors are designed to meet the demands for an environmental, high performance, rugged, moisture-sealed microminiature connector. Twist pin technology is a key feature of these connectors with 25 AWG pins or sockets on 0.050 (1.27) centers. Aluminum shells with Electroless Nickel finish provide good strength and offer excellent EMI and RFI protection. Stainless steel shells are also available for addition environmental integrity. Silicone elastomer interfacial seals provide a moisture and humidity seal between each contact and between contacts and shell.

MSWD Micro-D connectors are used in applications requiring highly reliable, extremely small, lightweight connectors with higher density contact configurations than available in traditional rectangular connectors. They are available in 7 shell sizes accommodating from 9 to 51 contacts with additional special arrangements available. These connectors are designed to meet the demands for an environmental, high performance, rugged, moisture-sealed microminiature connector. Twist pin technology is a key feature of these connectors with 25 AWG pins or sockets on 0.050 (1.27) centers. Aluminum shells with Electroless Nickel finish provide good strength and offer excellent EMI and RFI protection. Stainless steel shells are also available for addition environmental integrity. Silicone elastomer interfacial seals provide a moisture and humidity seal between each contact and between contacts and shell.

Materials and Finishes

| Aluminum Shell | 6061 Aluminum with Electroless nickel finish – In accordance with AMS-C-26074 or AMS2404. |

| Stainless Steel Shell | 300 Series Stainless Steel, Passivate – In accordance with AMS-QQ-P-35, AMS 2700, or ASTM A 967 |

| Insert | Liquid Crystal Polymer |

| Contacts | Copper Alloy, Gold Plated |

| Hardware | 300 Series Stainless Steel |

Mechanical Features

| Contact Spacing | 0.050 (1.27 MM) |

| Shell Styles | PLUGS and RECEPTACLES |

| Number of Contacts | 9 – 51 |

| Wire Size | # 24 AWG – # 32 AWG |

| Crimp Termination | Crimp |

Performance Data

| Dielectric Withholding Voltage | Method 3001: 600 VAC at sea level , 150 VAC at 70,00′ altitude |

| Insulation Resistance | Method 3003 |

| Thermal Shock | Method 1003. Condition A: -55C to +125C |

| Physical Shock | 500 cycles of mating and unmating, 500 CPH max |

| Vibration | Method 2005 Condition IV: 20 G’s, 10-2,000 Hz 12 Hrs |

| Durability | 500 cycles of mating and unmating, 500 CPH max |

| Moisture Resistance | Method 1002 , Type II modified |

| Salt Spray | Method 1001, Condition B: 48 hours |

| Contact Resistance - MIL-STD-202 | Method 1001, Condition B, @ 3 amps @1 milliamps |

| Content Retention | Per MIL-STD-83513 |

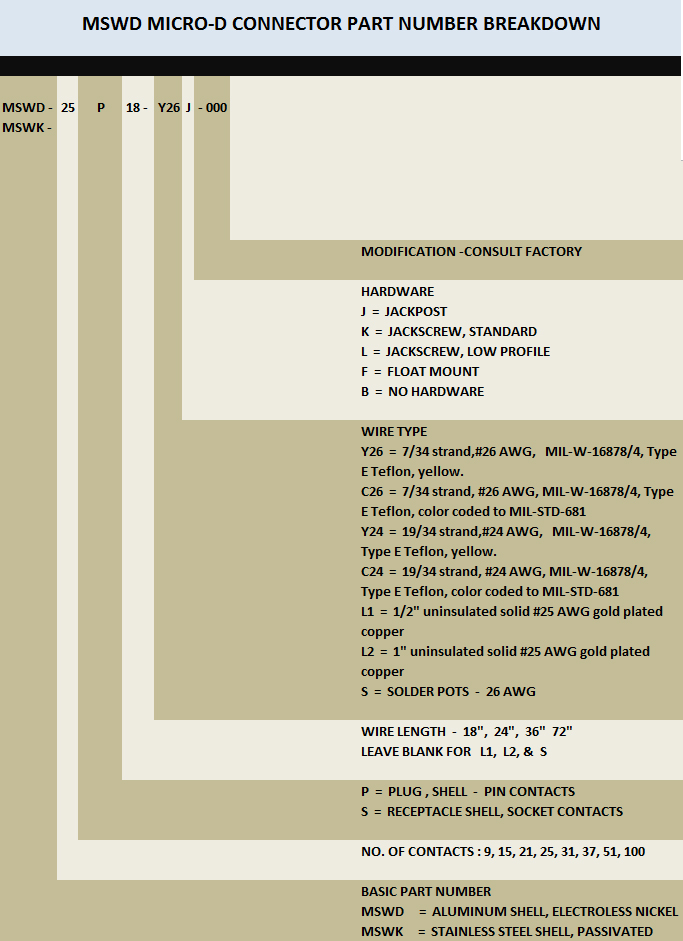

Part Number Breakdown